Commercial Boiler Chemistry Services in Minneapolis

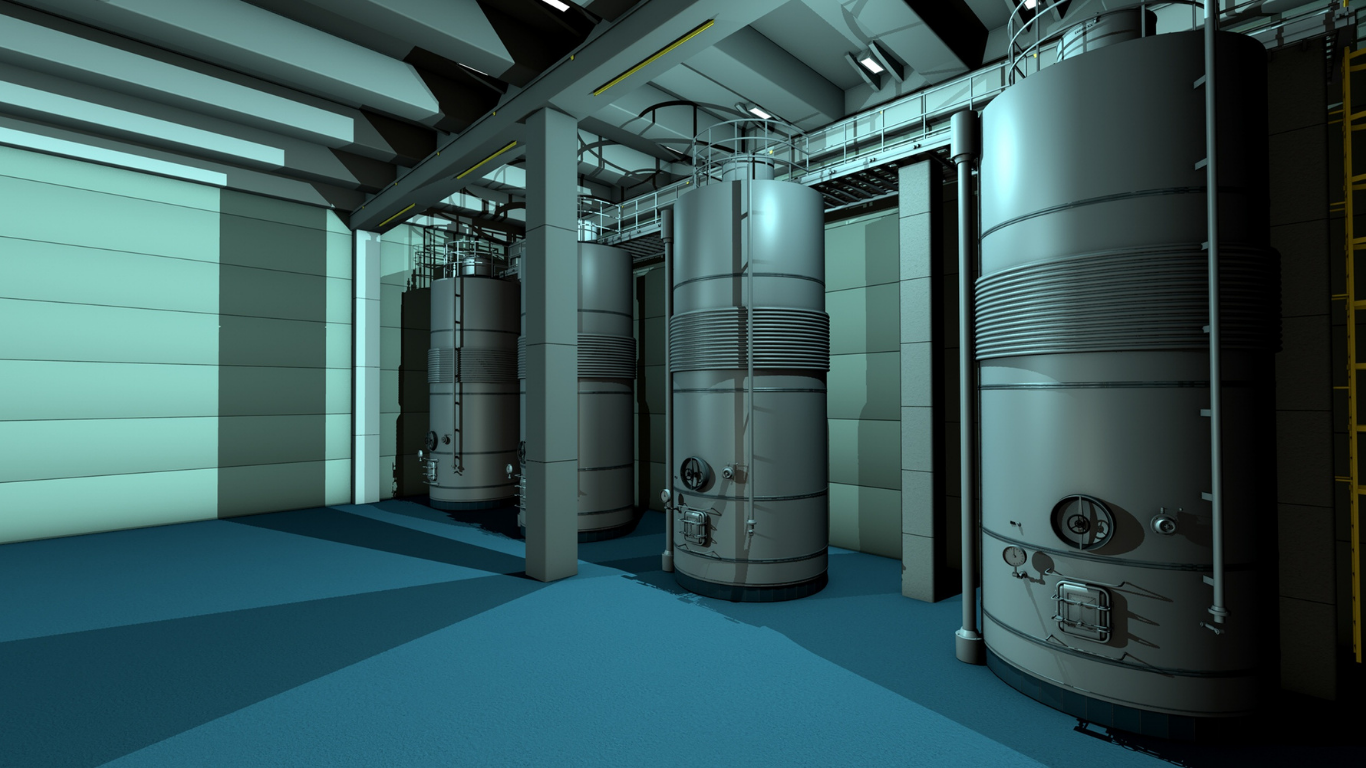

Protect Your System with Proper Water Treatment

Improper water chemistry is one of the leading causes of corrosion, scale buildup, and heat transfer inefficiency in steam boiler systems. For commercial buildings, maintaining clean, balanced boiler water is not only essential for performance — it is critical for the safety and longevity of the equipment.

Michael Toman Boiler license # MINNESOTA CHIEF A ENGINEER CA033678offers expert boiler chemistry services tailored to the unique needs of commercial steam systems in Minneapolis. With over two decades of experience and a Boiler license # MINNESOTA CHIEF A ENGINEER CA033678, he provides accurate testing, precise adjustments, and ongoing monitoring to ensure your boiler operates in peak condition.

What Is Boiler Chemistry and Why Does It Matter

Boiler chemistry refers to the treatment and regulation of water inside your steam boiler. Water that is untreated or improperly balanced can lead to:

- Corrosion of pipes and internal components

- Mineral scale buildup that reduces heat transfer

- Reduced energy efficiency and higher fuel costs

- Premature equipment failure

- Safety concerns due to pressure imbalances or blockages

By addressing these risks early, Michael helps commercial clients avoid costly repairs and maintain full operational efficiency year-round.

What This Service Includes

Michael’s boiler chemistry service is designed for thorough, regulation-compliant care of your system. Services include:

- On-site water testing for key indicators such as pH, conductivity, hardness, and dissolved solids

- Chemical treatment recommendations tailored to your specific system

- Corrosion and scale prevention protocols

- Monitoring and adjustment of feedwater and blowdown practices

- Documentation for compliance and future reference

Each step is performed with precision and care, using equipment and methods suitable for commercial-scale systems.

The Risks of Neglecting Boiler Water Chemistry

Many boiler breakdowns are caused by water-related issues that develop gradually. Without proper chemistry management, your system may be:

- Operating under increased pressure stress

- Using more fuel to achieve the same heat output

- Slowly damaging internal components due to corrosion

- Non-compliant with industry safety standards

Regular boiler chemistry services from a licensed operator reduce these risks and extend the useful life of your equipment.

Ideal for Commercial Properties in Minneapolis

Michael Toman serves only commercial clients. His boiler chemistry services are trusted by:

- Property managers

- Commercial landlords

- Building engineers

- Facility supervisors

- Steam plant operators

No residential or industrial services are offered — all work is tailored to the needs of Minneapolis commercial buildings and their specific compliance requirements

FAQs – Boiler Chemistry Services

What chemicals are used in commercial boiler treatment?

Chemical selection depends on your system’s makeup water quality. Michael uses corrosion inhibitors, scale reducers, and neutralizing agents based on tested needs.

How often should boiler water chemistry be checked?

Water chemistry should be monitored weekly, with detailed testing and adjustment as needed. For high-demand systems, more frequent checks may be required.

Is this service compliant with Minnesota boiler regulations?

Yes. Michael is fully licensed to monitor and adjust boiler systems in accordance with local codes and commercial safety standards.

Can poor water chemistry void equipment warranties?

Yes. Neglecting boiler chemistry can lead to damage that is not covered by warranties. Regular treatment ensures protection and proper system function.

Will this service reduce my heating costs?

Absolutely. Efficient heat transfer reduces the amount of fuel your boiler needs to operate, lowering monthly operating expenses.

Contact Michael Toman for Professional Water Treatment

Poor water chemistry can quietly destroy even the most well-maintained boiler. Do not let unseen damage shorten the life of your commercial steam system.

Call or email today to schedule a boiler chemistry service visit.

Phone:

(612) 384-2832

Email:

michael.toman@steamguy.net

Service Area: Minneapolis MN 55413

Business Hours: Monday through Friday, 8 AM to 5 PM

Michael Toman – EST. 2000

Boiler license # MINNESOTA CHIEF A ENGINEER CA033678